Dual Robot Workcell

*No Longer In Production

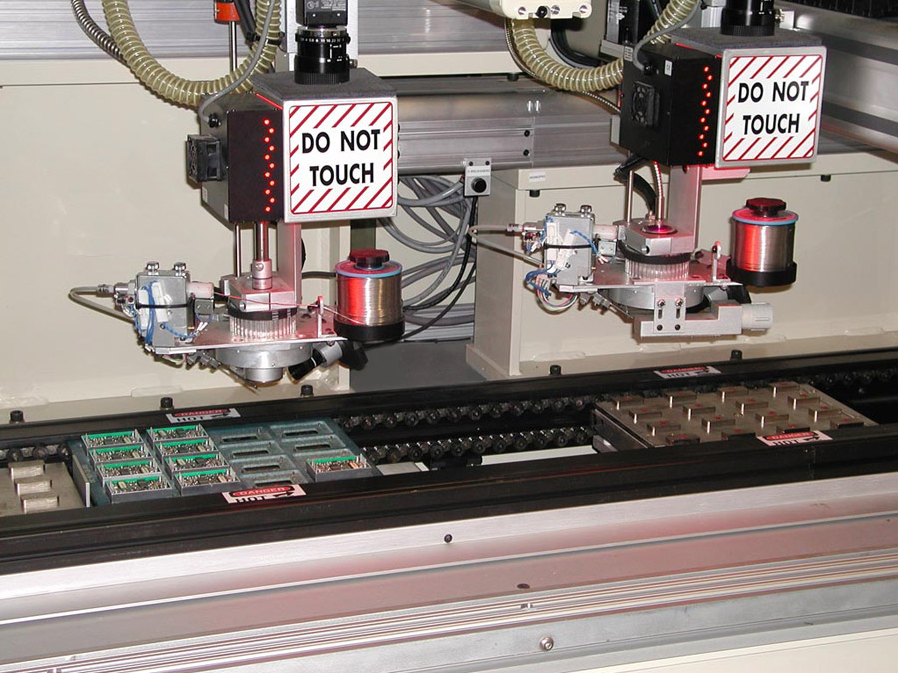

The Dual Robot Process Workcell has been developed to provide autonomous non-contact soldering when used in an in-line conveyorized production line. Pallets are automatically transferred into and out of the cell using an edge-type roller chain conveyor.

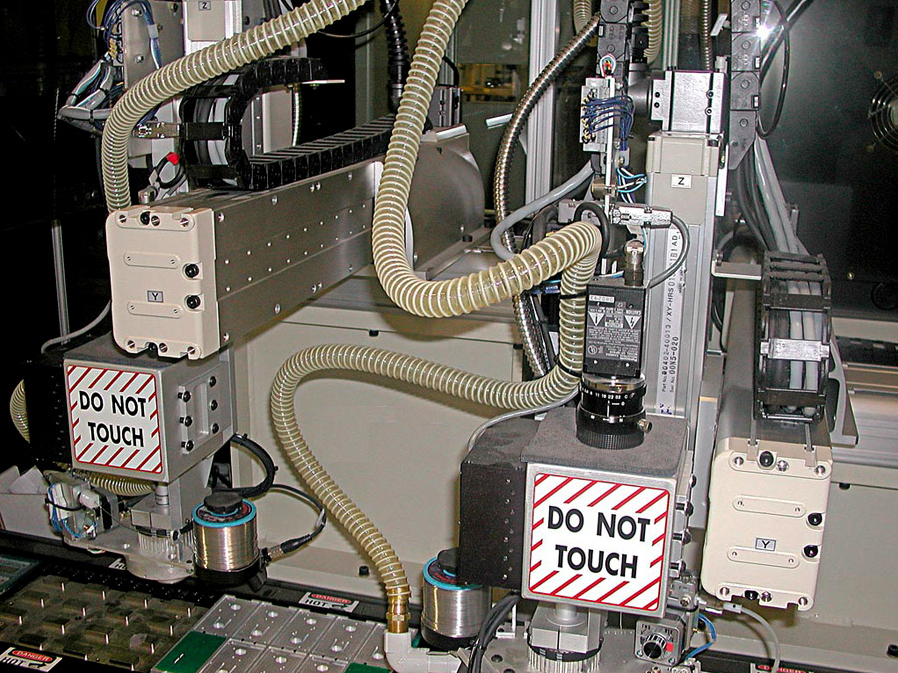

Two robots are used to selectively solder circuits using a non-contact Xenon arc fiber coupled heat source and a stepper-motor driven automatic solder wire feeder. Vision guidance along with two Cartesian robots is employed to position the focusing lens and solder feeder. Vision is used to assure that the location of the product to be soldered is accurately determined with a minimum reliance on mechanical positioning repeatability of the product to be soldered.

All components are first quality, industrial duty, and the design meets NFPA 79 guidelines as well as applicable safety standards.

Features

CONVEYOR SYSTEM

Heavy duty, chain drive, edge roller conveyor

Edge Rollers on 1.0” centers

Edge Roller affixed to Heavy Duty #40 Extended Pin Roller Chain

Bodine Gear Motor

Speed range: 1 ~ 20 FPM

Edge Clearance: 0.25” Standard

Conductive Chain & Bumper Guide Strips

ESD Protection

Conveyor Width: Adjustable 3” ~ 12”

Conveyor Height: Adjustable 35” ~ 37”,

Four Positions: Two input queue, two robot work positions

PALLET HEATING SYSTEM

Four pallet zones, two input queue, two robot work positions

Cartridge heaters embedded into pallet lift mechanism

Each pallet heat zone independently controlled (four total)

Temperature range: Ambient to 350°F

Control Type: Watlow PID (PWM) with SCR power control

Feedback type: Thermocouple embedded into pallet lift block

HEAT SOURCE

Dual Panasonic 60 Watt Non-Contact SoftBeam System

Beam Delivery: 6.5 mm dia. Fiber optic with focusing lens

Minimum Beam Diameter: 1.7 mm @ lens working distance of 18 mm

Maximum Beam Diameter: 5.7 mm @ lens working distance of 32 mm

Adjustable Power Range: 24 ~ 60 Watts

Power Adjustment: Controlled real time per process database

Bulb Type: Xenon Arc

Bulb Life: 1000 hours

Power Consumption: 3.9 kW per SoftBeam system

DIMENSIONS

72 ½” Wide X 52” Deep X 77 ½” Tall

Conveyor Height Adjustable from 35” to 37”

Conveyor Width Adjustable from 3” to 12”

MOTION AXES

X axes: 400 mm Adept H Module

Y axes: 350 mm Adept M Module

Z axes: 130 mm Sz Module

Theta Axes: Animatics Servo Motor / Gear box

XY Axes Repeatability: 0.0004”

REQUIREMENTS

Power: 460 VAC, Single Phase, 40 amps

Pneumatic: 80 ~ 120 PSI, non-lubricated air

USES

Clear Weld

Soldering

Screw Driving

Dispensing

Additional Features

GUARDING

Smoked polycarbonate interlocked per applicable safety standards

WORK-CELL / ROBOT CONTROLLER

An Adept AWC060 MV10 robot controller is used to control position of the two Cartesian robots, provide vision capability, and control the work-cell. The controller provides 28 tasks and abundant I/O for real-time work-cell control and allows unparalleled processing power and flexibility. Motion is highly coordinated and optimized for speed. An industrial flat panel touch-screen is used for operator interface to the controller.

OPERATOR INTERFACE

The operator interface is provided via an industrial touch-screen flat monitor . Simple to use GUI based process control menus allow real time modification of process parameters. Comprehensive help screens, operator messaging, and ease of use are major features of this platform.

MANUAL TEACH PENDANT

Industrial quality Adept teach pendant for manually moving the robot within the work space. The pendent displays robot coordinates, incorporates safety features to meet RIA safety standards, and allows the axis coordinates to be displayed and controlled in a variety of modes.

INDUSTRIAL I/O

Ruggedized Adept I/O technology and Bechoff DeviceNet IO are used to provide bulletproof optically isolated digital and analog I/O options for the work-cell. DeviceNet connectivity is supplied standard on the cell for ease of expansion.

POSITION/PROCESS TABLE

CAD data for the circuit pad locations and reference fiducials is used to define soldering locations for the robots. Actual product orientation is vision generated before moving to locations on circuit defined by CAD data. Databases containing vision, setup, and process data are stored in the controller memory. Separate process parameters for each solder location are stored in memory also. Multiple process setups / part numbers can easily be selected via menu.

PROGRAM LANGUAGE

System programmed in Adept V+, Adept AIM, Visual Basic (PC front end only with optional Adept Windows, not included)

VISION GUIDANCE

The system is supplies with Adept’s fully integrated VXL vision/motion guidance and inspection system. Ease of use, flexibility, and high performance are the hallmarks of this system. System setup is GUI based and requires minimal training. Two vision cameras and associated lighting are used to find the orientation of the product to be processed.

SOLDER PROCESS MONITOR AND CAMERAS

A miniature solder process camera is utilized on each of the two robots to provide a real-time, highly magnified view of the soldering process. The video image is displayed on a 13.5” JVC video monitor to aid in process development.

CONTROLS CONSTRUCTION

Per best industrial practices, all wires and terminals labeled per schematics, all pneumatic lines labeled, pneumatic manifolds labeled per function, disconnect interlocked main enclosure

AUXILIARY CONNECTIONS

Auxiliary air and AC connections are provided included on front of machine. SMEMA interface connections for in-line conveyor communication and operation are supplied standard.